Why Spare Parts Management for Plasma

Processes ?

|

- Any part in contact with the plasma impacts the

process.

- Spare parts are a major cost driver.

- So often second-source parts are used

– with sometimes different properties !

- The process stability depends in particular on

large-area parts:

- Surface temperature if not well controlled

(ceramics)

- Chemical surface conditions, in particular in case

of memory effects

- In particular if regularly cleaning during PM

causes seasoning

|

|

Spare parts management

|

- Scheduling

- Qualification and characterization of second source

parts

- Tracking and monitoring of age and cleaning cycles of

spare parts.

- Control:

- Product wafers → Message

comes usually too late.

- Test wafers

→ Necessary but not sufficient, not very

sensitive.

|

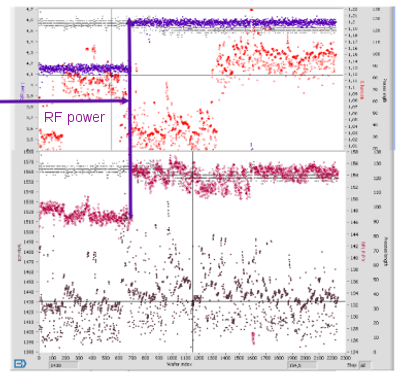

Low Pressure Process Example

|

-

Anisotropic

etching of dielectric with low damage

- CF4,

Ar

- Low

pressure 0.7 Pa (5 mTorr)

-

Medium

bias power, due to low pressure no collision in sheath

- → Low

but well defined ion energy keeps etch rate high but minimizes risk of

wafer damage.

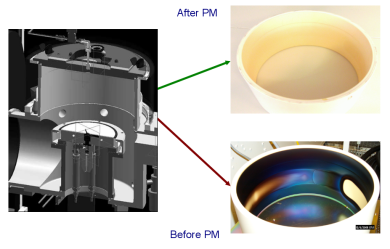

- Critical

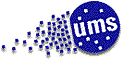

impact: Ceramic chamber wall changes during PM

- The most sensitive

tool parameters - RF peak voltages

at and does not respond to spare part changes and

process

adaptation.

- Collision

rate is in this low pressure regime only sensitive to

process

adaptation – due to stochastic heating of electrons.

|

|

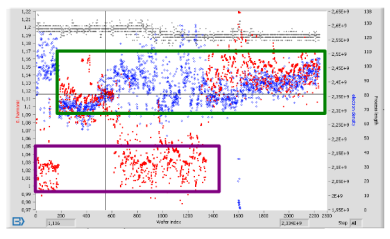

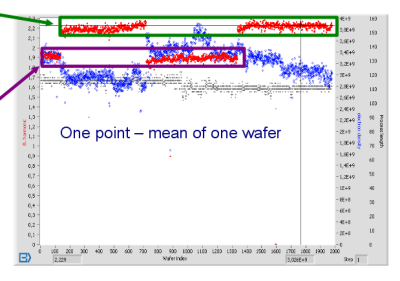

- Three

different ceramic parts – same level in plasma

current !

- One Second source ceramic - lower level.

- Plasma

density is also but less affected fits to products

parameters

still in spec.

|

|

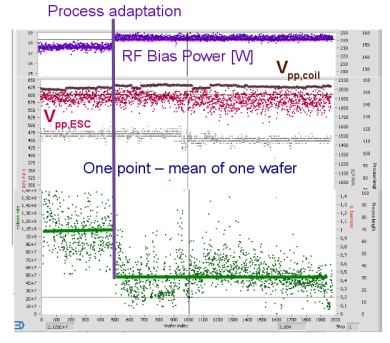

High

Pressure

Process Example

|

- Isotropic etching with low damage, surface

preparation and descum

- Low pressure 11 Pa (80 mTorr)

- Very low bias power

→ Mainly chemical (O)

etching with very low ion energy.

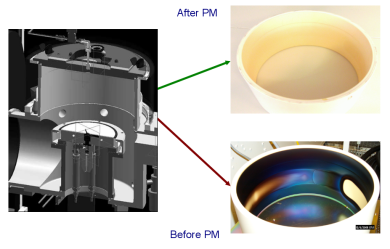

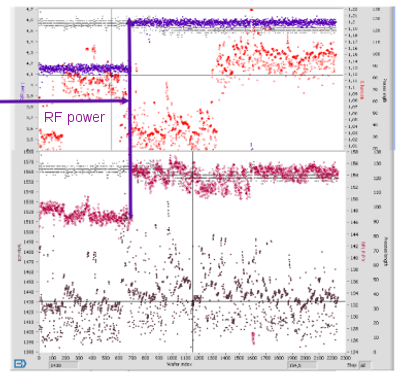

- Vp from coil shows

only a slight RF

power adjustment,

please compare RF power in diagram below.

- In both RF peak voltages no response to spare part

change.

|

|

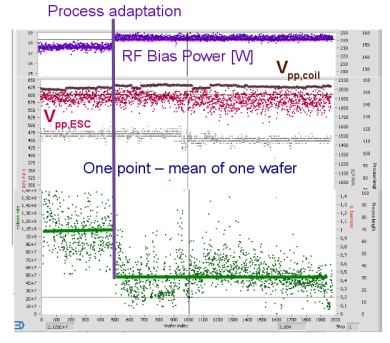

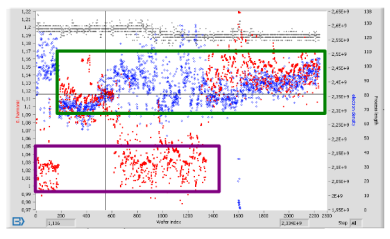

- Plasma

current

still shows the known, 'ceramic' pattern

clearly.

- Only weak pattern in plasma density.

- RF Power adjustment not seen here.

|

|

- … electron collision rate

indicates impact of gas temperature – due to ohmic heating of

electrons.

- Accommodation coefficient and so gas cooling at

chamber wall depends

strongly on surface conditions.

- Process

pressure adaption shown only through

collision rate.

|

|

- Process adaptation for etch rate and

selectivity is best reflected in plasma parameters.

- The effects of ceramic chamber wall as spare part

- is well pronounced in plasma parameters and

- depends on process, mainly the pressure.

- Potential reasons for impact of ceramic chamber wall:

- Variations in heat flow from gas to chamber wall

→ Gas

temperature.

- Different permittivity of the ceramics.

- Smart spare part management can be controlled by

plasma parameters

provided by model-based sensors.

|

- You are also welcome to contact our Services

Team to get additional information.

|