| REASON | DESCRIPTION |

|---|---|

| Idle time | Idle time causes the chamber to cool down and leads

to a first wafer effect, which is mostly seen in CDs, yield, etch or deposition rates. Typically, an idle time of half an hour or more leads to a first wafer effect, althrough sometimes as little as five minutes may have negative effects. The first wafer effect can be reduced warming up the chamber before the product lot is processed. |

| Process mix | Process mix is processing of different recipes (in

particular with variuos chemistry such as poly

and nitride etch) or

different products (various

open areas) at one chamber.

At large RF powers variation, the chamber reaches a new

temperature equilibrium which can be seen as a first

wafer effect. |

| Maintenance procedures | Maintenance procedures are

always an intrusion into the chamber and can also cause a first

wafer effect. Therefore, subsequent

reconditioning (warm-up or seasoning wafers) of the chamber is required. |

| Pre-process | First wafer effects can also be induced by pre-process and show a similar pattern as temperature related first wafer effects. For example, a mask process (hot plate or development) can lead to a well pronounced first wafer effect in the subsequent etch process. |

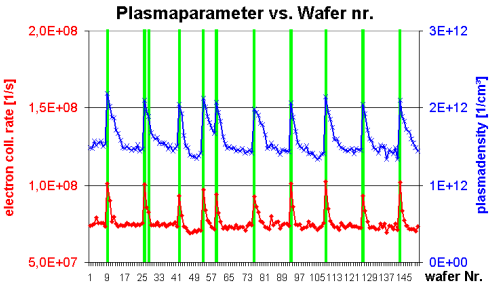

| Typical pattern: First wafer effect after dry clean at CVD process (green lines indicate the first wafer after dry clean) |

|