CONDITIONING: RE-CONDITIONING AFTER PREVENTIVE MAINTENANCE

Plasma chambers need preventive maintenance (PM) at regular

intervals due to:

- Films build-up from the deposition process or by-products

and resist mask fragments

- different life time of spare parts

- Erosion of surface anodization

- Exchange of end point detector quartz window and view port

glass

Installing refurbished or new chamber parts result

in process changes.

| REASON |

DESCRIPTION |

|

Wafer

number

|

The

number

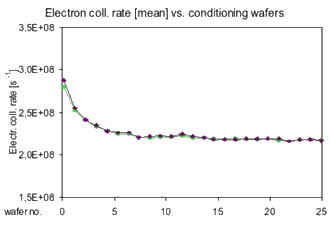

of wafers needed for conditioning is mostly determined empirically, and

often too many wafers and time are used for the

process. The

tool is not able to detect the conditioning status.

however, the

collision

rate is very sensitive to the chemistry at the chamber wall and can be

used as a status indicator when conditioning is complete. |

|

Wafer type

|

Complex

layer systems and processes require a series of conditioning

wafers such as:

- Blank

- Resist

- Oxide

- Structured conditioning wafers

Using incorrect wafer types (e.g., blamk Silicon) can reserve the

conditioning process. These de-conditioning effects can not be

detected by tool parameters. It requires a chemical

indicator

such as the electron collision rate. |

Insufficient conditioning can lead to process instabilities and yield

loss.

Using the electron collision rate and electron

density optimizes

the conditioning procedure, and increases tool uptime and OEE

(Overall Equipment Effectiveness). Once the plasma parameters

are

stable, chamber conditioning is complete. This enables dynamic

conditioning.

The electron collision rate and electron density can also used to

determine the sucess of other maintenance procedures.