CONDITIONING / ONE PRODUCT: PRODUCT AND PROCESS MIX

Process mix means using recipes with different chemistries in one

chamber. This usally leads to first wafer effects.

If a product or process mix is unavoidable, the first wafer effect can

be

controlled by product management. The optimum of the

product or process

switch depends on tool and process. The following link shows a comparison

of

continuous

processing or almost dedicated chamber operation.

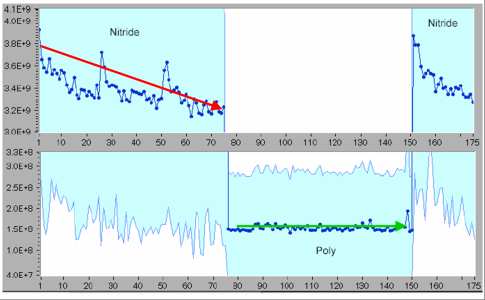

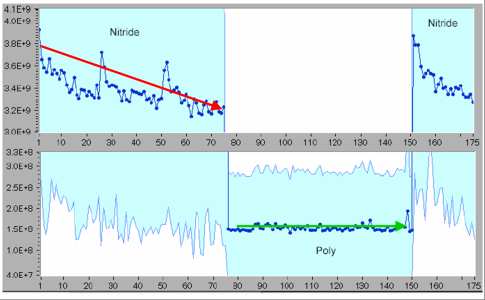

The deposition of byproducts at the chamber wall and in the vacuum

system leads to memory effects - when the underlying chemistry is

changed. This is due to diffusion of 'old' byproducts from the

pumping

system back into the chamber. It takes sometimes more than one wet

clean

cycle to reach the new chemical

equilibrium. The example below shows that about 4000

wafers needed to

get

a stable process.