The plasma parameters of conditioning procedure indicate the wet clean success immediately by:

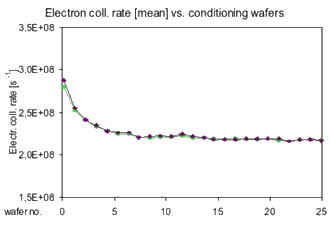

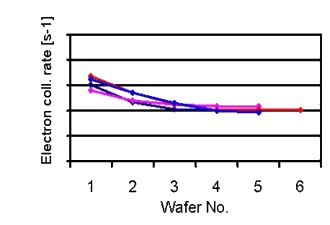

| The diagram below indicates normal conditioning: |

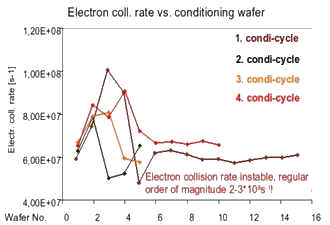

Plasma parameters are unstable with irregular magnitude changes compared to the diagram on the left: |

|

|

| Plasma parameters: Indicator of successful wet clean. |

Plasma parameters: Indicator of wet clean failure. |

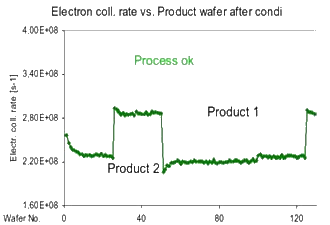

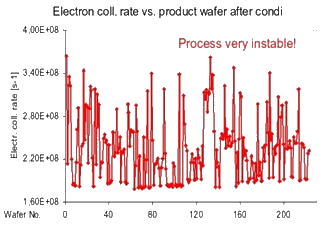

| Conditioning affects process stability: | |

|

|

| Stable conditioning --> stable process. |

Conditioning fault --> instable processing. |

| Goal:

Bring a

new

chamber into a similar conditioning state to yield the same processing

result as other chambers.

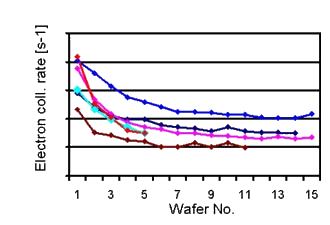

Chamber mismatch: Chambers have reached different steady states of chamber wall deposition. Example of poor chamber matching as indicated by the collision rate (for several conditioning cycles): |

|

|

| Chamber A: Stable | Chamber C: Unstable |

Deconditioning by wrong procedure

|

Depending on the

process, a proper conditioning procedure must be applied.

Select of suitable material for conditioning wafers is important ! Example: Metal Etch Process The use of blanc Si wafers can lead to a deconditioning, which can be seen in the collision rate: |

|

|

Use a suitable conditioning procedure ! |